Aerospace

Overview

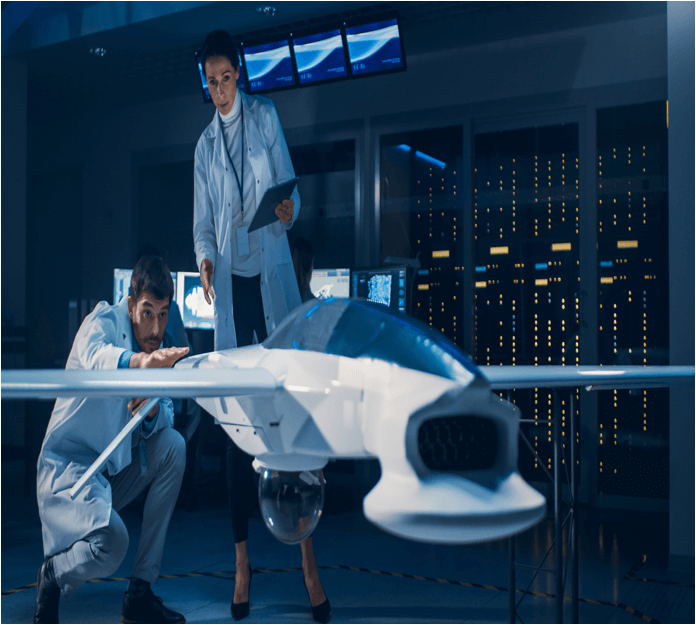

Pressurizing aerospace and defense OEM’s to innovate constantly is the constant struggle of today. Pressuring these OEM’s for designing small components, weights, costs, and time-to-market without compromising safety & security is a huge challenge for suppliers. These critical requirements combined with the growing pressure from digital transformation and customer expectations have made it necessary for suppliers to optimize business operations and practices. e-MUG takes pride in partnering with leading A&D companies to deliver value driven solutions that lead to positive outcomes. We undertake design & system level ownership of complex component, sub-systems, and modules ensuring that our customers can sustain a competitive advantage.

Services- Domains

Seating System

- Main Cabin

- Business Class

- Super First Class

- Business Jets

- Divans

Aero Interiors

- Oxygen Systems

- Structures & Monuments

- Galleys

- Crew Rests

- Monuments

- Lavatories

Passenger Service Areas

- LOPA 3D and 2D

- Cable and Harness

- Inflight Entertainment

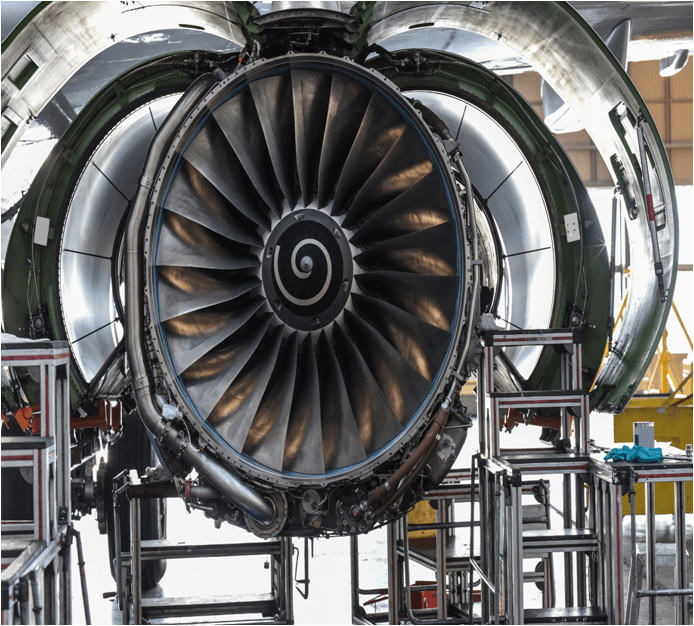

Aero Systems

- Landing Gears

- Hydraulics Systems

- Control Mechanism

Aero Structures

- Fuselage

- Wings

- Empennage

- Composites

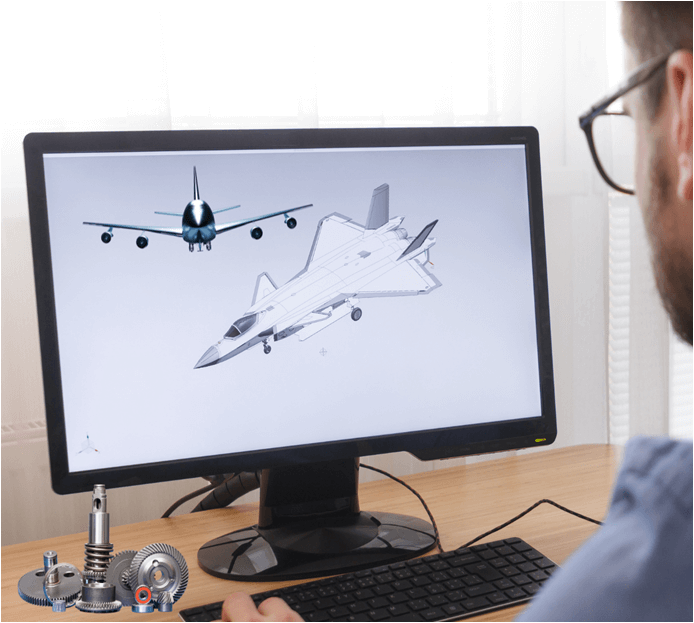

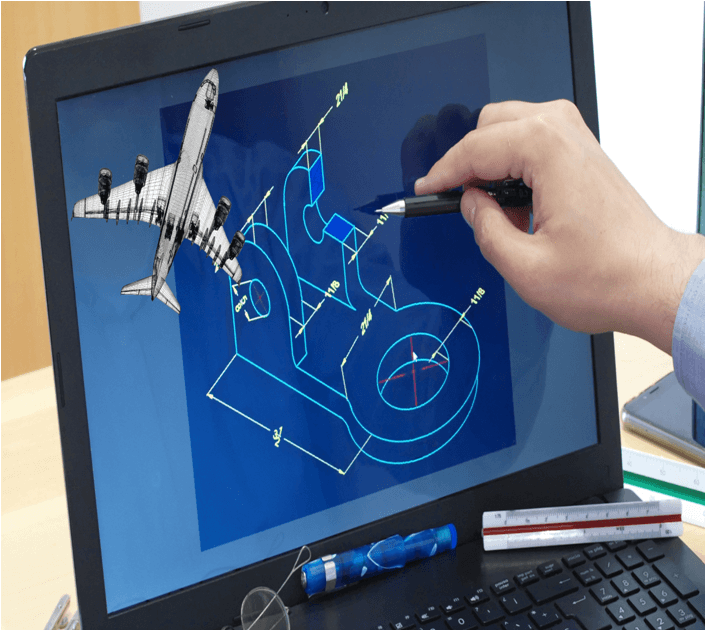

DESIGN

- Concept Proposal

- Alternate Designs

- Material Selection

- Process Selection

- Top-down Costing

- Product Evaluation

- Weight Saving Solutions

- Assembly Parts Reduction

- Optimisation

VALIDATION

- Hand Calculations

- Meshing and Model Build

- Stress Analysis

- Static and Dynamic Analysis

- Stress Structure Investigation

- Composite Structure Design

- Finite Element Analysis

- of composite components

- Failure Modes

- Layup Optimization

- Design Optimization

- Certification Reports

ENGINEERING

- CAD Modelling (Composites/Machined/Sheet Metal/Plastics)

- Detail Engineering

- Mechanism Design

- DFM & DFA

- Tolerance Study

- Sustenance Engineering

- Harness Routing and Installation

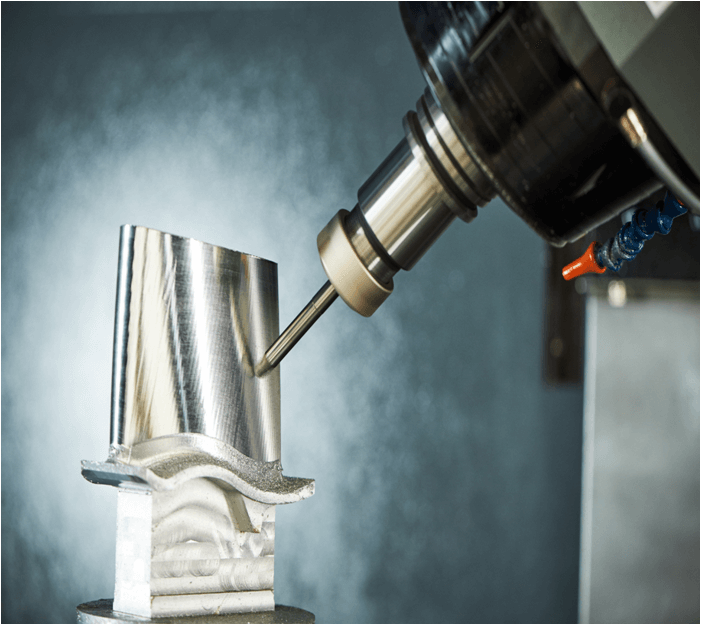

Virtual Manufacturing

- Virtual Manufacturing

- Fabric forming & draping

- Resin Curing

- Resin Infusion

- Material Permeability

- Isothermal

- Closed & Opened Mould

- Automated Prepreg technologies

- Machining

- Through Thickness Reinforcement

- Residual Stress and Distortion

MANUFACTURING

ENGINEERING SERVICES

- Tool, Mold, Die Design

- Jigs and Fixture Design and Detailing

- Welding Fixture Design and Detailing

- Simulation Design (Ergonomic & Safety)

- Factory & Facility Design

- Assembly Validation

- NC/CNC Programming

- Offline Robot Programming

- Standard Work Sheets

- Build Books (visual aids)

TECHNICAL

PUBLICATIONS

- Parts Catalogue

- Tech Illustrations

- Technical Manuals

- Interactive Manuals

Testimonials

Engage

At e-MUG, we believe in building long-lasting relationships with our clients. We understand that every project is unique and requires a tailored approach to meet specific needs. That’s why we offer various engagement models to ensure that we provide the best value and service to our clients. Whether it’s a short-term project or a long-term partnership, we are committed to delivering results that exceed expectations.

- Contact us through our website or email to discuss project requirements.

- Schedule a consultation with our team to determine the best approach for the project.

- Participate in our continuous improvement program to ensure ongoing success and optimization.

- Attend industry events and conferences where we have a presence to connect with us and learn more about our services.